The apparel industry, long characterized by mass production, complex global supply chains, and significant waste, is on the cusp of a revolutionary transformation. Artificial Intelligence (AI) and 3D printing are emerging as powerful forces set to redefine how clothes are designed, produced, and consumed, ushering in an era of hyper-personalization, efficiency, and sustainability.

AI: The Brains Behind the Smart Factory

AI’s impact on apparel manufacturing will be felt across the entire value chain, from initial design to supply chain optimization.

1. Hyper-Personalized Design & Trend Forecasting:

* Predictive Analytics: AI algorithms can analyze vast amounts of data—social media trends, runway shows, sales figures, climate patterns—to accurately predict future fashion trends, material demands, and even consumer preferences down to individual zip codes. This allows brands to produce only what is likely to sell, drastically reducing overproduction.

* Generative Design: AI can assist designers by generating novel design concepts, suggesting material combinations, and even creating entire collections based on specific parameters (e.g., target demographic, occasion, sustainability goals). This accelerates the design process and opens up new creative avenues.

* Virtual Fit & Customization: AI-powered body scanning and virtual try-on technologies will enable consumers to create highly accurate 3D avatars, ensuring perfect fit for custom-made garments. This will eliminate the need for traditional sizing, reducing returns and increasing customer satisfaction.

2. Optimized Production & Supply Chain:

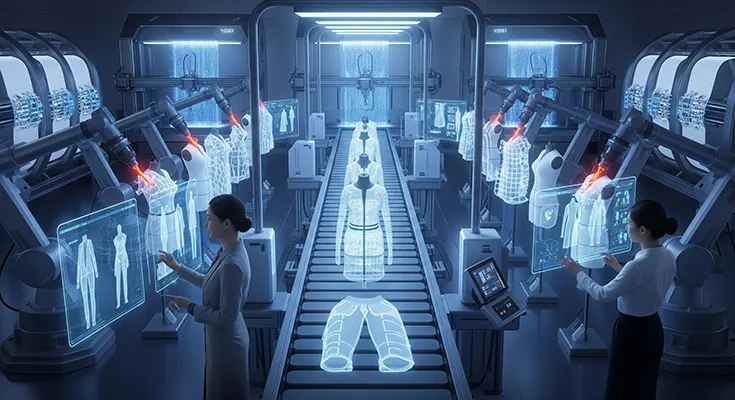

* Smart Factories: AI will power “smart factories” where production lines are fully automated, monitored, and optimized in real-time. Robots, guided by AI, will handle tasks like cutting, sewing (with advanced robotic arms), and packing with unparalleled precision and speed.

* Inventory Management: AI can accurately forecast demand at every stage of the product lifecycle, leading to just-in-time manufacturing and minimal inventory, freeing up capital and storage space.

* Quality Control: AI-powered vision systems can detect flaws in fabric or stitching with greater accuracy and speed than human inspectors, ensuring consistent quality.

3. Sustainability & Waste Reduction:

* Material Optimization: AI can optimize fabric cutting patterns to minimize waste, a significant issue in traditional apparel manufacturing.

* Circular Economy: AI can track materials and garments throughout their lifecycle, facilitating easier recycling and upcycling initiatives. It can identify what materials are available for reuse and guide the processes for breaking down and repurposing old garments.

3D Printing: Crafting the Future, Layer by Layer

While still in its nascent stages for mass apparel production, 3D printing (additive manufacturing) holds immense potential, particularly for bespoke items, complex structures, and sustainable material innovation.

1. On-Demand & Localized Production:

* Reduced Lead Times: 3D printing allows for rapid prototyping and on-demand production, eliminating the need for large minimum order quantities and long shipping times from overseas factories. This supports a move towards more localized manufacturing.

* Customization at Scale: Each garment or component can be uniquely tailored to an individual’s body measurements, aesthetic preferences, or specific functional needs (e.g., orthopedic inserts, personalized accessories).

2. Innovative Materials & Structures:

* Complex Geometries: 3D printing excels at creating intricate designs, textures, and structures that are impossible with traditional textile manufacturing. This could lead to entirely new aesthetics and functional properties in clothing.

* Sustainable Materials: Research is ongoing into 3D printing with bio-plastics, recycled materials, and even materials derived from algae or fungi. This opens the door to truly biodegradable and environmentally friendly apparel.

* Direct-to-Garment Components: While printing entire garments is still largely experimental, 3D printing is already being used for components like embellishments, buttons, shoe parts, and integrated smart sensors directly onto fabric, creating “smart textiles.”

3. Zero-Waste Manufacturing:

Additive manufacturing inherently reduces waste because material is only used where it’s needed, layer by layer. This contrasts sharply with subtractive methods (like cutting fabric) that generate significant scraps.

The Synergy: AI and 3D Printing Combined

The true power lies in the convergence of these two technologies. Imagine an AI designing a perfectly tailored, functionally optimized garment based on your body scan and preferences. That design is then sent to a 3D printer that fabricates the garment using sustainable materials, precisely creating complex structures and integrated functionalities.

* AI-Driven 3D Printing: AI will optimize the 3D printing process itself, determining the most efficient print paths, material densities, and structural integrity for each unique garment.

* Mass Customization: This synergy enables mass customization, where every item is produced to individual specifications without sacrificing efficiency or affordability.

Challenges and the Road Ahead

Despite the immense promise, challenges remain. The speed of 3D printing for large-scale textile production, the tactile feel of 3D-printed fabrics, and the development of a wider range of printable, wearable materials are all areas of active research.

However, the trajectory is clear. AI and 3D printing are poised to transform apparel manufacturing from a linear, resource-intensive process into a circular, intelligent, and highly responsive system. The future of fashion will be defined by smarter designs, more efficient production, personalized experiences, and a significantly smaller environmental footprint, stitched together by the threads of innovation.